Industries we Serve

Pharmaceutical & Cosmetics

Designing and building a range of dynamic mixers for pharmaceutical and cosmetic products worldwide

Manufacturing high-quality, reliable pharmaceutical and cosmetic mixing equipment requires deep knowledge of both the process and the product. At Transkem, our expertise in ingredient transfer, mixing, blending, product recovery, process control, sanitation, and cleaning enables us to choose the best mixing solution for our customers.

From simple turbine units for cough medicine to hydrogenator mixers that mix ingredients for paracetamol (Tylenol) and other common medicines, we carry a range of mixing equipment to suit a variety of needs and product types.

As a global leader in mixing and agitating equipment, many leading household pharmaceutical and cosmetic brands rely on our precise, accurate mixing solutions to manufacture toothpaste, medicine, hair gel, and many more essential products used around the world.

Precise, continuous mixing combined with expert process knowledge

We understand that mixing is not simply combining raw ingredients, but involves a deep knowledge of the chemical processes and material behavior of raw product when mixing and blending formulations for beauty, skincare, hair care, body care, oral care, personal care, and medicine. Each type of product requires a unique process, and our focus is to develop a customised solution that meets the customer’s high quality standards for the industry.

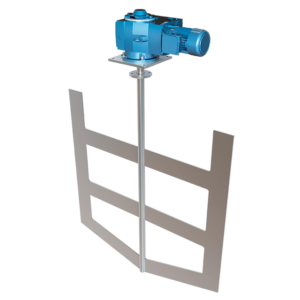

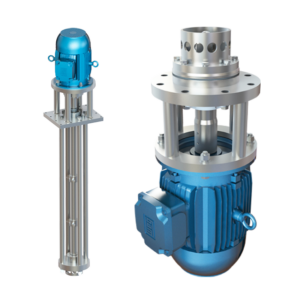

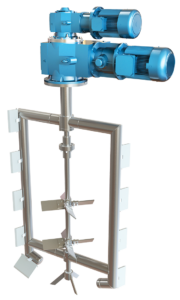

With our computer-aided design software and expert knowledge of the mixing process, we are able to accurately prescribe a custom solution to fit each task. Our gate mixers are often used for balms and simple creams, while many contra-rotating mixers and homogeniser combinations are ideal for manufacturing face creams, shampoos, and hair gels for some of the world’s top cosmetic brands. We even utilize contra mixer/emulsifier combinations for toothpaste manufacturing, and also have ribbon mixers operating as storage vessels for toothpaste, as well. All of our units can be customised with our customer’s choice of seal, motor, vessel size, and impellers to suit any size operation and viscosity.

With our expertise in pharmaceutical and cosmetic products, we can ensure your mixing operation runs smoothly with a continuous process and quality mixing at every step. Our units can be made to be fully hygienic and suited to all ATEX zones.

Our Products

The following mixers/agitators are commonly used in the Pharmaceutical & Cosmetics industry.

Click on the photos to learn more about each product.

Our Customers

Connect With Us

Reach out to us today to speak with our dedicated team.