Our Products

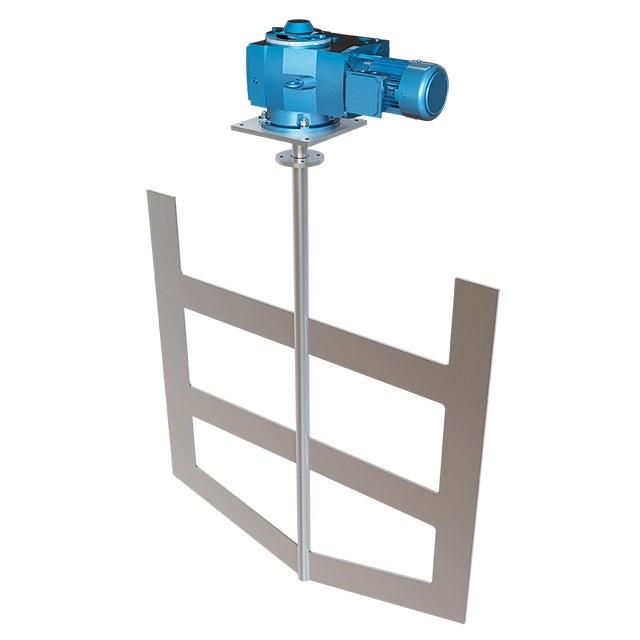

Gate Mixers

Ideally suited for sticky, highly viscous liquids, Transkem’s gate-type industrial fluid mixers can handle mixing products with viscosity up to 50,000+ cps.

Our line of Gate Mixers can be customised to meet our customer’s requirements, specific mixing duties, vessel geometries, and budgets.

Applications for Gate Mixers

Gate Mixers are ideal for sticky, highly viscous liquids that are characteristic of the food, beverage, pharmaceutical, and cosmetic industries. Our tough, reliable, and economic mixers are well suited for creams, shampoos, flocculants, heavy syrups, and other tough applications.

Gate Mixer Advantages

Also known as anchor mixers, Gate Mixers contain large diameter impellers with a close tolerance to the vessel wall. This helps to keep the sides of the vessel clear of product and aids in efficient heat transfer. To obtain adequate mixing, the impellers sweep the entire wall surface of the vessel, agitating most of the fluid batch through physical contact.

Customisation & Fitting Options

We can construct your unit with a variety of customisations and fittings for your ideal system, such as ptfe scrapers.

Materials

- 316, 316L Stainless Steel. Exotic Stainless Steel at customer’s request

Entry

- Top entry, or can be fitted on the horizontal plane for bottom entry

Fittings/Accessories

- Can be fitted with hinged scrapers to clear the vessel sides of product

Design Features

- Can be fully welded or bolt up design

Photo Gallery

Browse our image gallery to see actual photos of our Gate Mixers

Related Industries

Our Gate Mixers can meet the needs of a variety of complex industries.

Contact Us For a Quote

We pride ourselves on both quality and the ability to meet our customers’ needs—on time and on budget. Let us help you find the best fluid mixer solution to meet your requirements.