Our Products

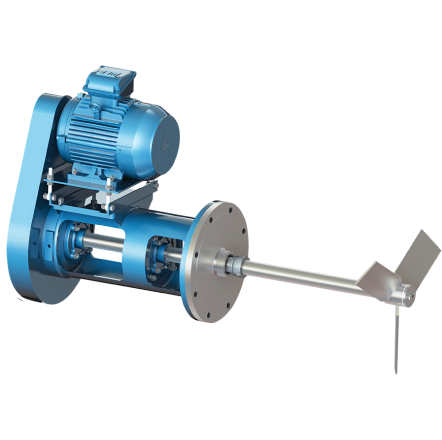

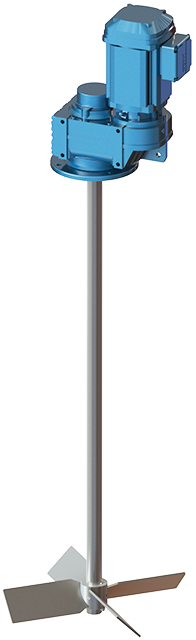

Turbine Mixers

A versatile mixer for almost every application.

From raw ingredients all the way through reactors to the end product, we’re experts in the complex mixing challenges of paints, varnishes, coatings, fine powdered pigments, and other viscous and thick products.

Applications for Turbine Mixers

Highly versatile mixers, Turbine Mixers are most often used for mixing lime slurries, food products, fine chemicals, and polymers. They are also suitable for solids suspension, and they also aid in heat transfer, mass transfer, and liquid blending.

Turbine Mixer Advantages

Transkem’s line of Turbine Mixers can ensure the most economical and efficient mixing solution with their versatility and ability to suit almost any application. Fitted with a wide range of turbines specifically designed for the mixing application, they can provide heat transfer, mass transfer, solid suspension, liquid/liquid blending, or whatever the process requires.

Customisation & Fitting Options

Turbine Mixers are highly customisable, and are explicitly designed to meet our customer’s specific requirements, such as material of construction, impeller selection, seal type, power consumption, and much more.

Materials

- Typically manufactured from Stainless Steel, but are available in various low corrosion alloys: Hastelloy, Inconel, Titanium, etc.

Size

- Manufactured with shaft lengths from 0.6m to 20 meters

Entry

- Can be top or bottom entry

Geared Motor Units & Seals

- Options to be fitted with the customer’s preferred gearbox, motor, and seal upon request

Fittings/Accessories

- Can be fitted with various impellers, ranging from simple pitched blade turbines, hydrofoils, to specially designed modules to suit all types of applications

- Can be fitted with various turbines to suit heat transfer, mass transfer, solid suspension, and liquid/liquid blending

Photo Gallery

Browse our image gallery to see actual photos of our Turbine Mixers

Related Industries

Our Turbine Mixers can meet the needs of a variety of complex industries.

Contact Us For a Quote

We pride ourselves on both quality and the ability to meet our customers’ needs—on time and on budget. Let us help you find the best fluid mixer solution to meet your requirements.