Our Products

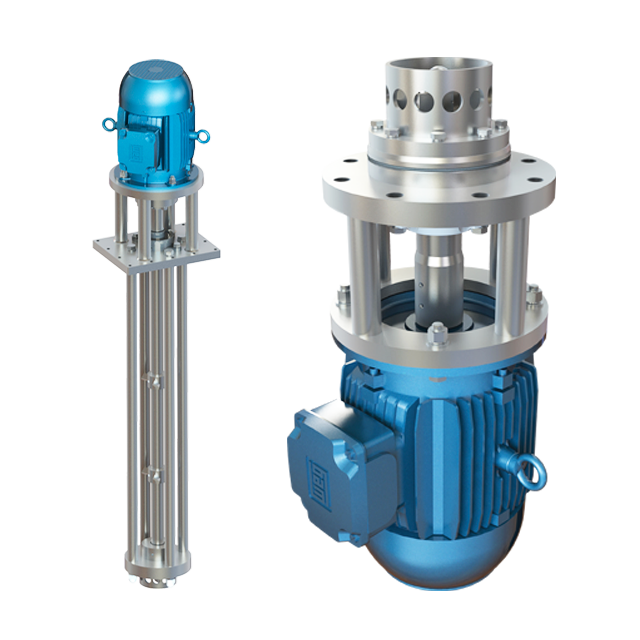

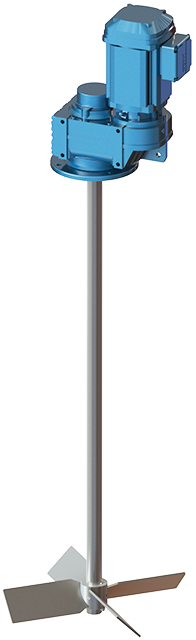

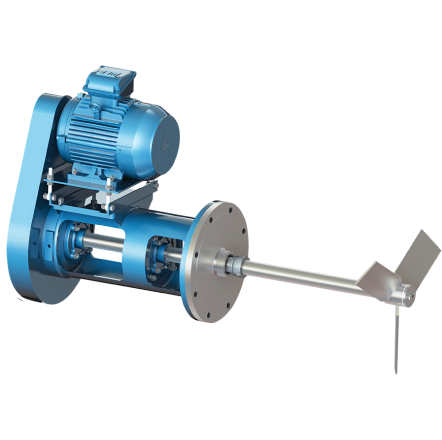

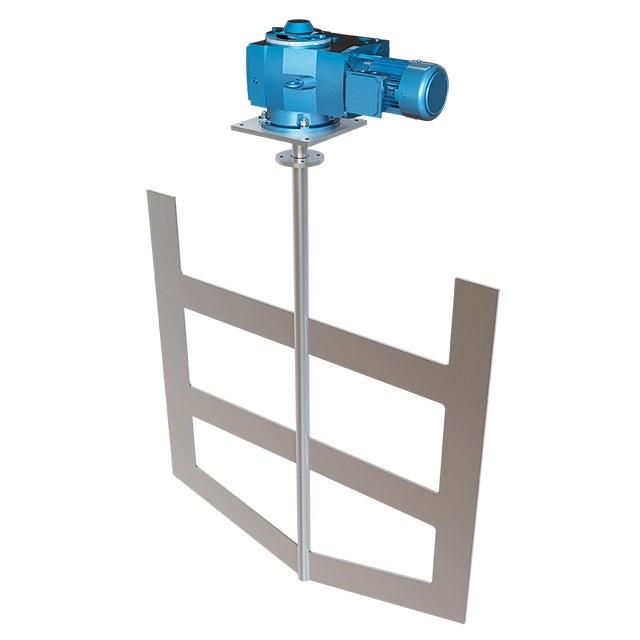

Economix

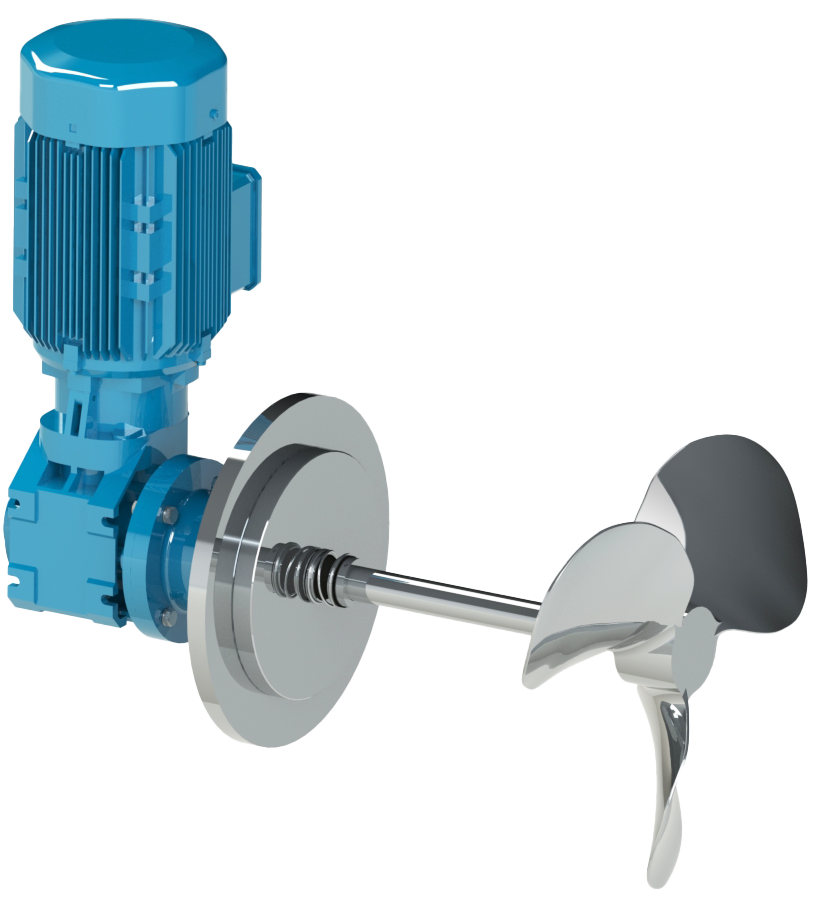

An affordable, reliable standard industrial side entry mixing solution for dairy and low viscosity liquids.

Our Economix line is a small side entry mixer, able to cost-effectively mix a variety of low viscosity liquids in bulk without compromising quality.

Applications for Economix

Economix is seen as the industry standard in dairy, with the ability to bulk mix milk and milk constituents, bright beer, potable water, and other low viscosity products. Light and portable, this line of mixers is ideal for the food industry and can mix other fine liquids with ease.

Advantages of Economix

With its simple design and construction, Economix has a proven track record of successful mixing, with thousands of units deployed throughout the dairy and brewing industries in the UK and beyond. This standard range mixer is effective and efficient while remaining one of our most affordable options for bulk mixing. The Economix is also very easy to maintain.

Customisation & Fitting Options

The Economix line is a standard range mixer that is not available to customise, although units can be supplied with the customer’s choice of vessel flange to suit connection to the vessel.

Materials

- Stainless steel wetted parts / carbon steel bodies

Entry

- Side entry

Design Features

- Reliable and easy to maintain

Fittings/Accessories

- Units can be supplied with vessel flanges to suit connection to the vessel

Related Industries

Our Economix line meets the needs of a variety of complex industries.

Contact Us For a Quote

We pride ourselves on both quality and the ability to meet our customers’ needs—on time and on budget. Let us help you find the best fluid mixer solution to meet your requirements.