Our Products

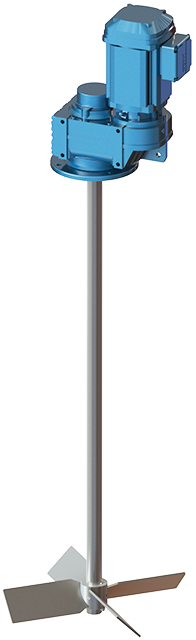

Ribbon Blenders

Rapid, smooth blending for even the most challenging mixing applications.

Our double-start helical ribbon blender allows thorough mixing of extremely viscous products and is best at blending viscosities greater than 50,000 cps.

Applications for Ribbon Blenders Applications for High Shear Mixers

This mixer is a proven workhorse in many industries and can effectively mix toothpaste, cosmetics, adhesives, polymers, and other viscous products within minutes.

Ribbon Blender Advantages

Consisting of inner and outer helical blades called ribbons, this durable industrial mixer uses counter-directional flow while keeping the product in constant motion throughout the vessel. Combined with hinged scrapers, our ribbon blenders are great for helping to clean the side wall of the vessel when emptying sticky, viscous products.

Customisation & Fitting Options

Our ribbon blenders are highly customisable and can be further enhanced to suit your specific needs, mixing duty, and vessel size and shape. A range of fittings and accessories can be added to produce your ideal ribbon blender.

Materials

- 316, 316L. Exotic Stainless Steel at customer’s request

Entry

- Can be fitted in the vessel along with a Transkem bottom entry emulsifier/homogeniser or in some cases, where the helical ribbon mixer is small, a top entry homogeniser/emulsifier

Design Features

- Double start helical ribbon type, but can also be supplied with a single scroll only

- The wet end can be completed, or can be supplied in parts to be assembled within the vessel

Fittings/Accessories

- Can be fitted with or without footsteady in-tank bearings

- Can be fitted with the customer’s preferred seal and drive, with double or single mechanical seals

- Can be fitted with ATEX drives

Photo Gallery

Browse our image gallery to see actual photos of our Ribbon Blenders

Related Industries

Our Ribbon Blenders can meet the needs of a variety of complex industries.

Contact Us For a Quote

We pride ourselves on both quality and the ability to meet our customers’ needs—on time and on budget. Let us help you find the best fluid mixer solution to meet your requirements.